Polyurethane Model Blocks

Our architectural model block products are produced as standard as 80-100 kg / m3 low density and 80-100 kg / m3 high density.

Our architectural model block products are produced as standard as

80-100 kg / m3 low density and 80-100 kg / m3 high density.

We produce 150, 200, 250, 400, 500, 600, 800, 1.000 kg / m3

density upon request.

Our architectural model blocks are kept in the upper porch area open to

the atmosphere during curing, and our blocks, which have completed their

dimensional stability, are sized by subjecting to the fast cutting system.

| Density (Kg/m3) | Comprressive strength (Kpa) | Young’s modulus (N/mm2) | Flexural strength (Kpa) | Tensile strength (Kpa) | Operating temperature (°C) |

|---|---|---|---|---|---|

| 80 | 800 | 19 | 1150 | 700 | -120/+120 |

| 100 | 1100 | 30 | 1300 | 850 | -120/+120 |

| 120 | 1200 | 30 | 1500 | 1000 | -120/+120 |

| 150 | 1600 | 38 | 2000 | 1150 | -120/+120 |

| Density (Kg/m3) | Length x Width (mm) | Height (mm) |

|---|---|---|

| 80 | 2000 x 1000 | 500 / 400 |

| 100 | 2000 x 1000 | 500 / 400 |

| 120 | 2000 x 1000 | 500 / 400 |

| 150 | 2000 x 1000 | 200 |

| 250 | 2000 x 1000 | 200 |

| 350 | 2000 x 1000 | 100 |

| 500 | 2000 x 1000 | 100 |

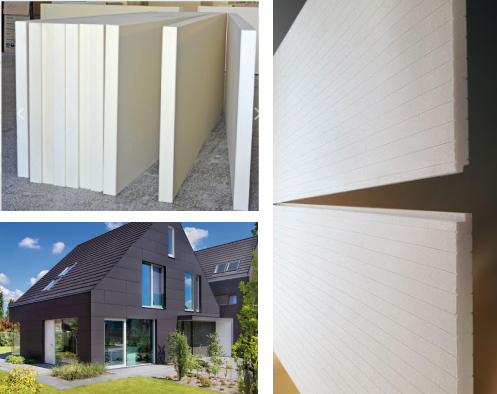

Waterproof and High Insulation Body Isolation

Polyurethane facade materials are the extreme points your dreams can reach They are decorative products that you can realize.

The biggest deficiency we noticed in the construction industry is in exterior and

interior facades; Our architects, engineers and project owners were unable to realize

precast designs or faced high costs in other precast products. Therefore, our

company switched to polyurethane precast and coating products without mold limit.

Since our polyurethane products are very light and durable (130-250 kg / m3

density), they do not add extra weight to your buildings like other precast products.

Polyurethane facade materials are decorative products that you can realize

to the extreme points your dreams can reach. One of the reasons why

Polyurethane Precast is preferred is that it offers unlimited model options

with clear lines in competent hands. It perfectly adapts to external

conditions.

It is very light compared to Concrete Precast. There is no dimensional limit if

it is produced by manufacturing companies that follow process conditions

and technological developments. It can be produced as a monoblock.

Provides perfect finishes after application. It is not even possible to compare

Styrofoam foam materials, which are produced as Exterior Facade

Accessories in our country and applied on facades, in terms of life and

performance.

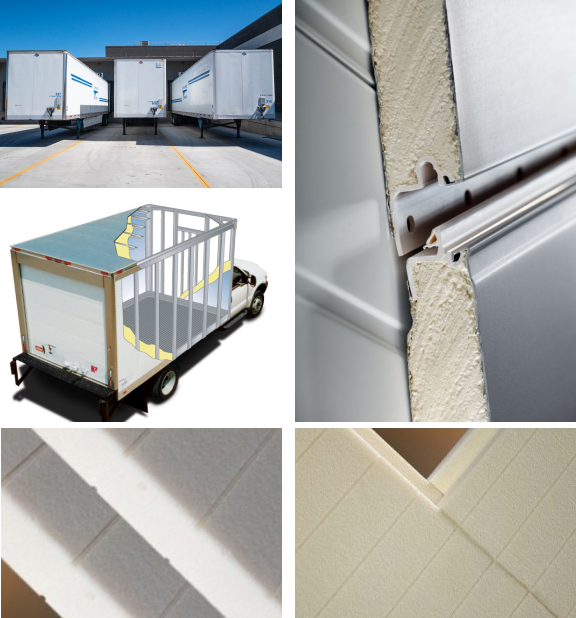

Cooler Insulation/ Insulation Polyurethane Foam

Low density polyurethane is used as thermal insulation material in the production of panels used in box design for trucks and trailers with heat insulation.

Low density polyurethane is used as thermal insulation material in the production of panels used in box design for trucks and trailers with heat insulation. Low density polyurethane foams are available in densities ranging from 35 to 60 kg / m3. It has been specially developed to meet the requirements of trailers and trucks. It makes it an excellent choice for insulation applications with very low thermal insulation coefficients (lambda = 0.022 W / mk).

Technical Specifications

Heat insulated body plates: Prepared for thermally insulated frame plates. Our standard tongue, groove and 2x2 adhesive adrenance striped polyurethane panels on the bottom and top surface of the plate every 50 mm.

| Yalıtım Materyali / Insulation Material | C PIR (Poliizosiyanurat) |

|---|---|

| Malzeme/Material | 35-37-40-42-50 kg/m3 yoğunluğunda (± 2) |

| Standart Ölçülerimiz / Our Standard Dimensions | |

| Uzunluk/Length | 2.000 mm. / 2.500 mm. / 2.750 mm. / 3.000 mm. |

| Genișlik/Width | 1.000 mm. / 1.200 mm. |

| Kalınlık/Thickness | 20 mm. ve 500 mm. arası |

| Malzeme/Material | 35-37-40-42-50 kg/m3 yoğunluğunda (± 2) |

| Yalıtım Materyali / Insulation Material | PUR (Poliüretan) |

| Standart Ölçülerimiz / Our Standard Dimensions | |

| Uzunluk/Length | 2.000 mm. / 2.500 mm. / 2.750 mm. / 3.000 mm. |

| Genișlik/Width | 1.000 mm. / 1.200 mm. |

| Kalınlık/Thickness | 20 mm. ve 500 mm. arası |

PIR

Poliisocyanurate

(Developed

Polyurethane

Foam)

Polyurethane Facade materials are decorative products that you can achieve the most extreme points your dreams can reach.

Surfaces such as pipes, equipment, tanks that pass through cold and fluid are

insulated with materials such as PIR, PUR, which are produced as

prefabricated in order to prevent energy passes from outside. Various vapor

inhibitors such as liquid or laminated foils are used in practice. Glass wool

material for protection is wrapped on the anti-vapor application. Then,

protection is provided by covering the insulation materials with protective

sheets such as PVC, aluminum, galvanized, stainless steel.

It addresses a wide range of pipe insulation. It

can be used between -196 ° and + 110 °.

If double-walled material is preferred, a perfect insulation at +200

degrees is obtained. As the life time will be longer than other insulation

applications, it provides personnel protection in pipelines within walking

distance of the bridge lines and provides non-deformable and

non-crushing pipe insulation with its great bearing feature.

Advantages of Polyurethane Foam Insulation

- 40% reduction in heat loss

- Easy setup

- Resistance of polyurethane foam to various effects

- Environmental Safety

- No temperature limitation at runtime

- Possibility to reuse the shell of the foam

- Resistance to rot, pests and chemicals

- Possibility to use in a wide temperature range

- Fire security

- Repeated use

- Ecological compatibility

- Minimizing the repair cost of pipelines

Contact with Whatsapp

Contact with Whatsapp